-

Establishment Date: 08.11.2018

-

Investment in Instruments: 500,000 RMB

-

Key Instruments: Hexagon CMM, Mitutoyo Roughness Tester, Vickers Hardness Tester, Contour Measuring Instrument

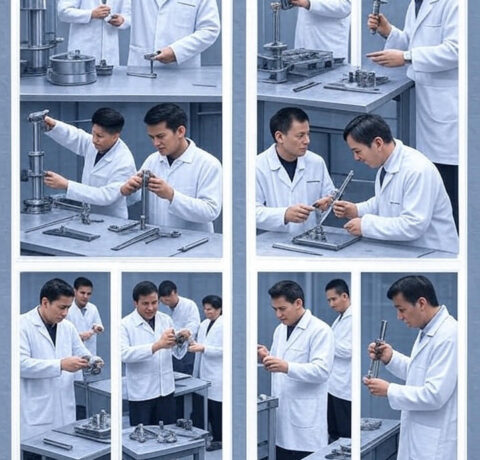

Advanced Inspection Instruments for Unmatched Accuracy

At Tingko (Shanghai) Co., Ltd., our commitment to precision is supported by state-of-the-art inspection instruments that ensure every Swiss-type machined part meets the highest standards. These tools are integral to maintaining tolerances as tight as 0.001mm and surface finishes up to Ra 0.005μm, critical for industries like medical, automotive, and communications. Our inspection capabilities include:

- Hexagon Coordinate Measuring Machine (CMM): Provides 3D dimensional analysis with precision down to 0.001mm, ensuring accurate geometric validation.

- Mitutoyo Roughness Tester: Measures surface roughness with high accuracy, ideal for polished components used in 5G connectors and medical devices.

- Vickers Hardness Tester: Assesses material hardness post-machining or heat treatment, guaranteeing durability for transmission parts.

- Contour Measuring Instrument: Profiles complex geometries like valves and worms, supporting our micro-part expertise (minimum diameter 1 mm).

Our advanced inspection tools, calibrated daily, ensure 100% quality coverage, making Tingko a trusted name in precision manufacturing.

These instruments are operated by our skilled 17-member team in a controlled environment, with regular calibration and full traceability protocols. Integrated with our Japan Star SB20R machining setup, they enable real-time quality feedback during 24-hour production shifts, supporting custom orders and surface treatments like PVD and anodizing. Clients receive detailed inspection reports, reinforcing our dedication to excellence and reliability.

Suspendisse malesuada venenatis

Our investment in inspection technology extends to ongoing training, ensuring our engineers master the latest techniques. This proactive approach minimizes rework, enhances efficiency, and aligns with our quality policy of continuous improvement. Whether it’s a prototype or high-volume batch, our instruments deliver consistent results, positioning Tingko as a leader in precision machining solutions.

-480x460.jpg)

Tingko (Shanghai) Co., Ltd. is committed to excellence in Swiss-type CNC machining, delivering precision parts with 0.005mm tolerance from our Shanghai base, serving global industries with integrity and innovation.

Tingko (Shanghai) Co., Ltd. is committed to excellence in Swiss-type CNC machining, delivering precision parts with 0.005mm tolerance from our Shanghai base, serving global industries with integrity and innovation.